Introduction

In the pursuit of energy efficiency and extended range, aerodynamics play a pivotal role in the design of electric vehicles (EVs). Unlike traditional internal combustion engine (ICE) vehicles, EVs rely solely on electricity to power an electric motor. This shift in power source calls for a reevaluation of vehicle aerodynamics to enhance efficiency, extend range, and ultimately, advance the capabilities of electric mobility.

1. The Significance of Aerodynamics in Electric Vehicles

The aerodynamic performance of a vehicle is a critical factor in determining its energy consumption and range. Unlike conventional vehicles, which often have excess power available from their engines, electric vehicles rely entirely on stored energy. Therefore, any improvements in aerodynamic efficiency directly translate into increased range, making it a key consideration in the design process.

2. Key Aerodynamic Elements in EV Design

a. Streamlined Body Design

One of the primary considerations in enhancing aerodynamics is the overall shape of the vehicle. A streamlined body design minimizes air resistance, allowing the vehicle to move more efficiently through the air. This is achieved through features such as sloping roofs, tapered front ends, and strategically placed curves.

b. Underbody Paneling

Aerodynamic considerations extend beneath the vehicle. Smooth underbody paneling helps to reduce turbulence and drag. By minimizing air disturbance under the vehicle, designers can significantly improve overall aerodynamic performance.

c. Active Aero Features

Incorporating active aerodynamic features, such as adjustable flaps and spoilers, allows for dynamic adjustments based on driving conditions. These features can optimize airflow at higher speeds for reduced drag, or adjust to improve cooling during extended periods of high demand.

3. Case Studies: Exemplary Aerodynamic EVs

a. Tesla Model S: Setting the Standard for Aerodynamic Excellence

When it comes to aerodynamic design in electric vehicles, the Tesla Model S stands as a shining example of what’s achievable. With a drag coefficient of an astonishing 0.21, the Model S redefines the possibilities of aerodynamic efficiency. Its sleek, low-profile body, combined with features like flush-mounted door handles and an automatically retractable spoiler, work together to significantly reduce air resistance. This meticulous attention to aerodynamics contributes not only to extended range but also to an enhanced driving experience with reduced wind noise and improved stability at high speeds.

b. Nissan Leaf: Merging Form with Function

The Nissan Leaf, a stalwart in the electric vehicle market, seamlessly blends practicality with aerodynamic efficiency. Boasting a drag coefficient of 0.28, the Leaf exemplifies how thoughtful design can enhance electric vehicle performance. Its distinctive front-end design and gently sloping roofline contribute to its aerodynamic profile without compromising interior space. By carefully managing airflow around the vehicle, Nissan engineers have successfully maximized efficiency without sacrificing the vehicle’s overall functionality.

c. Volkswagen ID.3: Striking the Balance Between Style and Efficiency

Volkswagen’s ID.3 is a testament to the marriage of cutting-edge design and aerodynamic performance. With a drag coefficient of 0.267, the ID.3 exemplifies how aerodynamic considerations can be seamlessly integrated into a vehicle’s aesthetic. Its clean lines, sculpted sides, and distinctive LED light strip on the front create an appealing visual profile while also contributing to reduced air resistance. This combination of form and function allows the ID.3 to deliver an impressive balance between style and efficiency in the realm of electric mobility.

d. Porsche Taycan: Performance and Aerodynamic Prowess

While Porsche is renowned for its high-performance vehicles, the Taycan demonstrates that speed and aerodynamic efficiency are not mutually exclusive. Despite its powerful electric drivetrain, the Taycan achieves a drag coefficient of 0.22, a remarkable feat for a vehicle of its class. Carefully sculpted lines, an active rear spoiler, and adjustable air intakes exemplify Porsche’s commitment to aerodynamic excellence. By seamlessly integrating high-performance capabilities with aerodynamic design, the Taycan showcases the potential for electric sports cars to redefine the standards of efficiency in the automotive industry.

d. BMW i4: Precision Engineering Meets Aerodynamic Prowess

The BMW i4 is a standout in the electric vehicle landscape, showcasing how precision engineering and aerodynamic design can synergize for outstanding efficiency. With a drag coefficient of 0.23, the i4 exemplifies BMW’s commitment to aerodynamic excellence. Its sculpted lines, distinctive kidney grille, and carefully designed air curtains contribute to its impressive aerodynamic profile. By seamlessly integrating advanced engineering with aerodynamic innovation, the i4 exemplifies BMW’s dedication to pushing the boundaries of electric mobility.

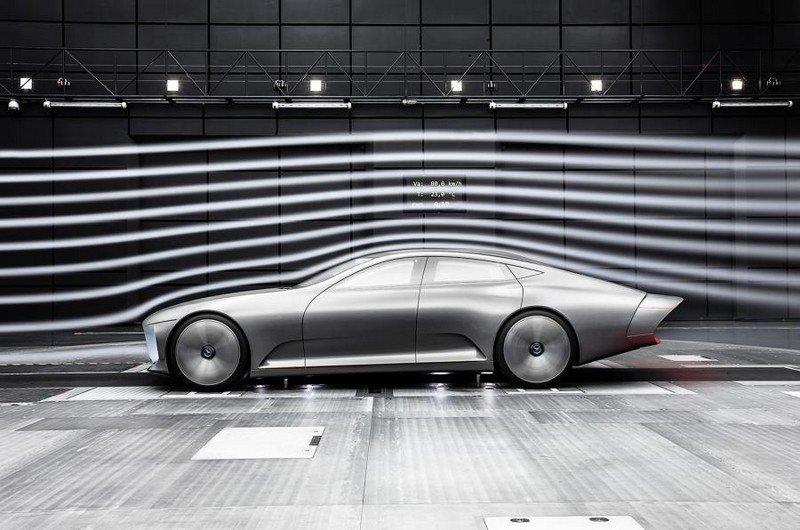

4. Wind Tunnel Testing and Computational Fluid Dynamics (CFD)

To validate and refine aerodynamic designs, engineers employ advanced testing techniques. Wind tunnel testing provides real-world data on a vehicle’s aerodynamic performance. Additionally, computational fluid dynamics (CFD) simulations enable engineers to predict and analyze airflow patterns around the vehicle, allowing for iterative improvements in design.

5. Balancing Aerodynamics with Aesthetics and Practicality

While aerodynamics are paramount for efficiency, they must be balanced with other design considerations. Aesthetic elements, safety features, and practical considerations such as cargo space all play a role. Skilled designers integrate aerodynamic principles seamlessly into the overall design, creating vehicles that are both functional and visually appealing.

Conclusion: The Future of Aerodynamics in Electric Mobility

As the automotive industry continues its transition towards electric mobility, the role of aerodynamics becomes increasingly pivotal. Efficiency gains achieved through aerodynamic design directly impact the range and overall performance of electric vehicles. By pushing the boundaries of aerodynamic innovation, designers are not only advancing the capabilities of EVs but also shaping the future of sustainable transportation.